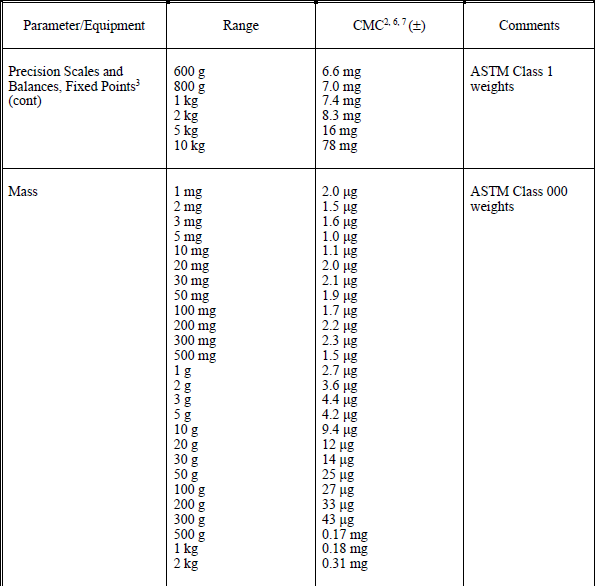

We offer A2LA ISO 17025 accredited calibration for regulated operations and NIST traceable services for internal quality programs, providing the precise documentation and measurement confidence your applications demand. Our comprehensive weight calibration services cover test weights, ASTM weight sets, OIML weight sets, and certified reference mass standards from 1mg to 10kg.

We understand what keeps quality assurance managers awake at night—the fear of failed audits, missing calibration documentation, and equipment that drifts out of tolerance at the worst possible moment. That’s why our weight calibration services deliver more than just measurements. You get comprehensive, audit-ready documentation that satisfies even the most demanding regulatory inspectors.

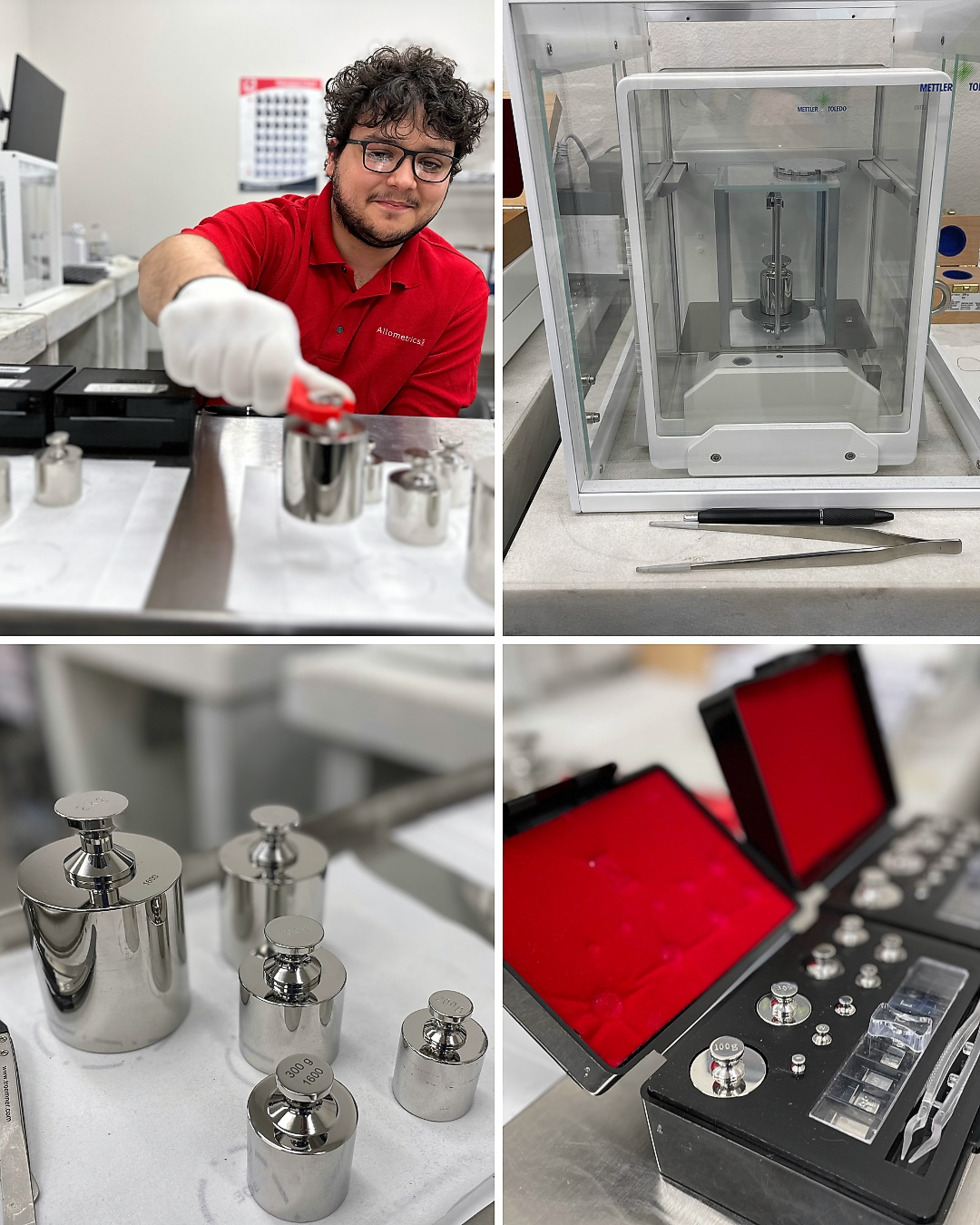

Our mass metrology lab is A2LA Laboratory Accredited for weight calibration. This accreditation signifies a stamp of approval for technical competence in weight calibration services.

What makes our weight calibration services different:

- ISO 17025 accredited laboratory with industry-leading calibration uncertainties

- NIST traceable certificates that provide legally defensible measurement documentation

- Emergency response options when you need urgent calibration to avoid production delays

- Nationwide service coverage with consistent quality across all your facilities

- 50+ years of proven expertise serving pharmaceutical, chemical, food processing, and manufacturing industries

When auditors review your calibration records, our documentation consistently passes inspection. That’s our commitment to your operational success.

About A2LA and NVLAP

The American Association for Laboratory Accreditation A2LA, together with the National Voluntary Laboratory Accreditation Program (NVLAP), represents the leading accrediting body for laboratory testing and calibration companies.

Weight Calibration Equipment We Service

Our laboratory calibrates precision weights and certified reference standards from 1mg to 10kg, servicing the exact equipment you depend on for regulatory compliance and quality control.

Precision Weights & Mass Standards:

- Individual precision weights (1mg to 10kg range)

- Complete ASTM weight sets (Class 1 and Class 000 weights)

- Certified reference standards

- Analytical micro-weights

- Industrial mass standards

- Laboratory calibration weight sets

Major Equipment Brands We Calibrate:

- Troemner

- Mettler Toledo weights

- Rice Lake Weighing Systems

- ASTM weight sets (all manufacturers)

- OIML weight sets (all manufacturers)

- Certified reference weights (all brands)

Whether you’re calibrating a single analytical weight or maintaining an entire set of ASTM Class 1 reference standards, our ISO 17025 accredited laboratory delivers the measurement accuracy and documentation your auditors demand.

Industries That Rely on Our Weight Calibration Services

Precision weight measurements form the foundation of quality control across regulated industries where accuracy isn’t just important—it’s legally required.

Pharmaceutical & Biotechnology: API manufacturing, quality control laboratories, compounding pharmacies, clinical research facilities, and contract manufacturing organizations requiring FDA and cGMP compliance.

Food & Beverage Processing: Production quality labs, ingredient batching and receiving, finished product testing, package verification, and food safety programs meeting HACCP and FDA standards. [1]

Chemical Manufacturing: Raw material measurement, batch formulation processes, quality assurance laboratories, R&D operations, and environmental testing facilities requiring EPA and OSHA compliance.

Healthcare & Clinical: Hospital laboratories, clinical diagnostic labs, medical device manufacturing, reference laboratories, and research institutions.

Industrial Manufacturing: Quality control departments, production measurement systems, metrology laboratories, aerospace and defense operations, and electronics manufacturing requiring precise mass standards.

Additional Industries: Environmental testing laboratories, educational and research institutions, government regulatory agencies, contract testing labs, and any organization requiring NIST traceable weight measurements.

Whether you’re meeting FDA compliance in pharmaceutical manufacturing, maintaining HACCP standards in food processing, or ensuring quality in chemical production, our weight calibration services deliver the measurement accuracy and documentation your operations demand.

Why Organizations Trust Allometrics for Weight Calibration

When audit results depend on measurement accuracy, experience and accreditation aren’t just nice to have—they’re essential. Here’s why organizations across pharmaceutical, food processing, chemical manufacturing, and industrial sectors choose Allometrics as their weight calibration partner.

Understanding Weight Calibration and Why It Matters

What Is Weight Calibration?

Weight calibration is the documented comparison of your precision weights against certified reference standards with known, traceable values. Through this process, we determine if your weights meet their specified tolerances and provide official documentation proving measurement accuracy.

Think of it this way: your analytical weights might display “100.000 grams,” but without calibration, you have no proof that reading is accurate. Our ISO 17025 accredited laboratory compares your weight against NIST traceable standards, measures any deviation, and documents the results. This creates the measurement traceability chain that auditors require and your quality system depends on.

The calibration process verifies your weights perform within manufacturer specifications and regulatory requirements, meeting the documented standards your quality system demands.

Your Specifications, Our Precision: You specify the calibration standards, tolerance requirements, and intervals based on your quality system and standard operating procedures. Our role is to perform the calibration to your specifications and provide the comprehensive NIST traceable documentation you need for compliance.

Benefits of Professional Weight Calibration Services

Regulatory Compliance Confidence

Your FDA, ISO 9001, or cGMP compliance depends on traceable measurement documentation. Our NIST traceable certificates provide the proof auditors demand, eliminating anxiety about inspection findings.

Accurate Product Formulation

In pharmaceutical compounding, chemical batching, or food processing, minor weight measurement errors compound into significant problems. Calibrated weights ensure formulations match specifications every time, protecting product quality and patient safety.

Defensible Measurement Data

When regulatory agencies question your test results or compliance data, NIST traceable certificates defend your measurements, proving your weights were accurate when critical measurements were made.

Equipment Performance Monitoring

Regular calibration identifies drift before it causes quality issues. This predictive insight prevents failed batches, recalled products, and production shutdowns from undetected measurement errors.

Cost Avoidance

Failed audits, production delays, and product recalls cost exponentially more than routine calibration. Professional weight calibration is quality insurance that pays for itself the first time it prevents a compliance failure.

Simplified Multi-Facility Management

For operations directors managing quality across multiple locations, our nationwide service delivers consistent calibration standards, uniform documentation, and centralized scheduling—one vendor partner instead of managing dozens of local calibration companies.

The Hidden Risks of Neglecting Weight Calibration

Audit Failures and Regulatory Actions

FDA warning letters, failed ISO audits, and State Boards of Pharmacy sanctions frequently cite inadequate calibration documentation. These compliance failures damage reputation and can shut down operations until corrected. Discovering calibration problems during an audit creates emergency situations—expedited fees, production delays, overtime remediation costs, and potential penalties that cost exponentially more than scheduled preventive programs.

Lost Customer Confidence

Nothing erodes trust faster than measurement quality problems. Whether it’s pharmaceutical wholesalers questioning your testing or food service customers doubting package weights, uncalibrated equipment undermines your market position.

Compromised Product Quality and Invalid Test Results

Uncalibrated weights silently introduce errors into every measurement-dependent process. In pharmaceutical manufacturing, this means API concentrations outside specifications. In food processing, nutritional labels that don’t match contents. When weights drift out of calibration, months of laboratory testing becomes questionable. Organizations face devastating consequences: retesting archived samples, investigating suspect batches, recalling distributed products, or defending regulatory challenges without defensible measurement data.

Personal Career Impact

For quality assurance managers, calibration failures during audits become resume events. Preventable compliance findings reflect on professional competence and advancement potential. Our weight calibration services help protect both your organization and your career.

Get Audit-Ready Weight Calibration Services Today with Allometrics

Your regulatory compliance and product quality depend on measurement accuracy you can prove. Don’t risk audit findings, production delays, or compromised measurements with uncalibrated weights.

What You Get with Allometrics:

Comprehensive A2LA ISO 17025 Accredited Service

From individual precision weights to complete ASTM weight sets, we calibrate the exact equipment your operations depend on—from 1mg micro-weights to 10kg reference standards.

Documentation That Satisfies Auditors

Every calibration includes detailed NIST traceable certificates with complete measurement data, uncertainties, environmental conditions, and standards used. The documentation that regulatory inspectors demand.

Convenient Laboratory Service

Send your weights to our A2LA ISO 17025 accredited laboratory for calibration with highly competitive measurement uncertainties

Emergency Response When You Need It

Discovered a missed calibration before an audit? Critical weights showing unexpected drift? Our emergency calibration service can help prevent production shutdowns and compliance failures.

Serving Quality-Critical Operations Nationwide

Based in Webster, Texas, we provide weight calibration services throughout the United States. Whether you’re in pharmaceutical manufacturing, food processing, chemical production, healthcare, or industrial operations, we deliver the measurement accuracy and compliance documentation your industry demands.

Our Service Area and Capabilities

Nationwide Weight Calibration Coverage

Our nationwide network means multi-facility operations work with one calibration partner instead of managing dozens of local vendors. Consistent service delivery, standardized documentation, and simplified vendor management across your entire operation.

Emergency Response When You Need It

Equipment doesn’t fail on your schedule. When audit findings require immediate calibration, when critical weights show unexpected drift, or when you discover missing due dates, our emergency calibration service responds to urgent situations. We’ve helped countless quality managers avoid production shutdowns with expedited calibration options.

Flexible Scheduling That Fits Your Operations

We work around your production schedule, not the other way around. Weekend calibration, off-shift service, and coordinated multi-equipment maintenance windows minimize disruption to your critical operations.

How Our Calibration Process Works

Step 1: You Define Requirements

You specify your calibration standards, tolerance levels, and service intervals based on your quality management system and regulatory requirements.

Step 2: We Execute to Your Specifications

Our ISO 17025 accredited laboratory performs calibration following your documented requirements using NIST traceable reference standards.

Step 3: You Receive Complete Documentation

We deliver comprehensive calibration certificates with all measurement data, uncertainties, environmental conditions, and standards used—ready for your auditors.

Not sure what specifications you need? Our team can provide guidance on industry-standard practices, but the final calibration requirements are always determined by your quality system.

Your Weight Calibration Requirements & Compliance Questions Answered

The recommended calibration frequency for precision weights depends entirely on your specific quality system and regulatory requirements. So we can’t really give you a universal answer. You determine the calibration intervals based on your standard operating procedures, how you use the weights, and what your auditors or regulatory bodies require. Some pharmaceutical operations calibrate quarterly, while others with less critical applications might calibrate annually. We track your chosen schedules and send advance reminders to help you stay on top of due dates, but the interval decision stays with your quality management system.

Yes, regular calibration for weighing equipment is absolutely necessary. Without regular calibration, you have no documented proof that your weights are accurate—and proof is exactly what auditors demand. We’ve seen what happens when organizations skip calibration: FDA warning letters, failed ISO audits, compromised product quality, and invalid test results that force expensive retesting and recalls. Weights drift over time from normal use and environmental factors. Regular calibration catches this drift before it causes quality issues, failed batches, or audit findings. It’s not just necessary—it’s quality insurance that protects your operations, your compliance status, and frankly, your career.

Our A2LA ISO 17025 accredited service provides independent third-party verification of our technical competence—this is what regulated industries like pharmaceutical manufacturing, medical devices, aerospace, and food processing require because it includes documented measurement uncertainties and undergoes rigorous annual audits. Our standard NIST traceable service offers cost-effective calibration for internal quality programs where full accreditation isn’t required by your auditors. Both maintain the legally defensible measurement chain your operations depend on. The choice depends on your regulatory requirements and what your auditors demand—and we’ll help you understand which service level your situation needs.