Temperature, humidity and pressure mapping is a Good Manufacturing Practice (GMP) designed to help companies monitor and maintain the confines of an overall environment. This process is intended to prevent temperature and humidity fluctuation in a controlled area or environment whether it is a clean room, warehouse, refrigerator, freezer, oven, autoclave, or vehicle. Temperature mapping may also be referred to as thermal mapping.

Temperature, humidity and pressure mapping might be performed on a regular interval to conform with FDA CGMP or other GMP guidelines or as part of an Installation Qualification Operation Qualification (IQOQ) or Performance Qualification (PQ)

What is Temperature and Humidity Mapping?

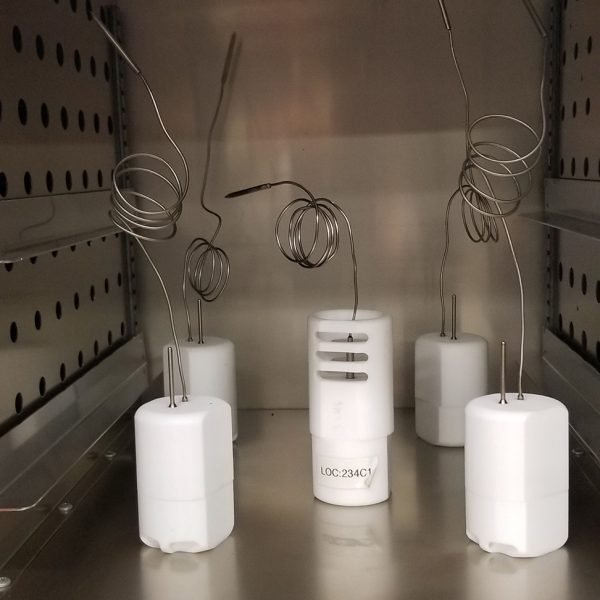

Mapping refers to the process of recording the temperature and humidity levels in a 3-dimensional space. To create the visual plan or map of the environment or enclosure, technicians place multiple dataloggers throughout the space. These dataloggers allow the user to see the temperature and humidity for each chosen location within the environment to be mapped.

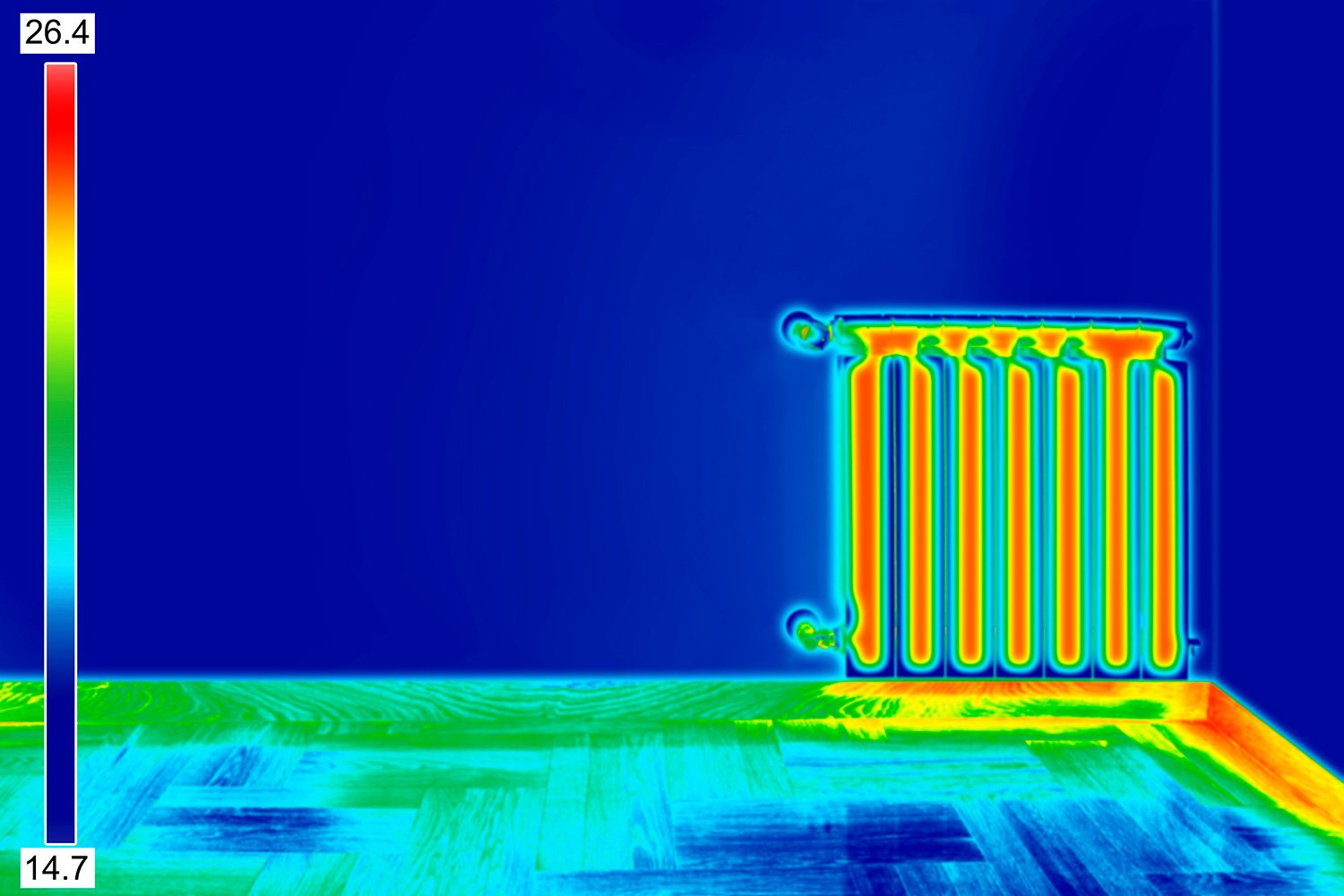

A common assumption is that temperatures and humidity levels in autoclaves, controlled environment rooms, freezers, refrigerators, incubators, and environmental chambers are uniform throughout the space. However, temperature, humidity, and pressure readings can vary significantly from one location to another.

Why is Temperature and Humidity Mapping Important?

Temperature and humidity mapping should be a standard part of a company’s GMP guidelines to detect and correct areas with inconsistencies to ensure proper storage conditions and regulatory compliance. When incorporated into a standard GMP or quality system, temperature and humidity mapping can aid in the prevention of product and monetary loss, as well as improve overall quality and public safety.

For example, if a pharmaceutical manufacturer or compounder only mapped a few areas throughout their storage facilities or warehouse, they may fail to identify temperature abnormalities in other areas. Drugs placed in those overlooked areas could be distributed with harmful side effects or be entirely ineffective.

Who Requires Temperature Mapping?

Temperature mapping is typically required by regulatory agencies in industries where maintaining specific temperature conditions is critical for product quality, safety, and efficacy.

The list of organizations that must comply with existing storage and distribution practices includes but is not limited to, the following:

- Manufacturers of drug products for human and veterinary use

- Packaging operations by the manufacturer or a designated contractor

- Repackaging operations

- Laboratory operations at the manufacturers or the contractor’s site

- Physician and veterinary offices

- Pharmacies including but not limited to retail, compounding, specialty, mail order, hospital, and nursing home pharmacies

- Importers and exporters of Record

- Wholesale distributors; distribution companies involved in automobile, rail, sea, and air services

- Third-party logistics providers, freight forwarders, and consolidators

- Healthcare professional dispensing or administering the drug product to the end-user

- Mail distributors, including the U.S. Postal Service (USPS) and other shipping services, such as expedited shipping services

- Border Customs storage areas

What Needs to Be Mapped?

- Mixers

- Ovens

- Refrigerators / Freezers

- Sterilizers

- Autoclaves

- Stability Chambers

- Freeze dryers

- Incubators

- Hot rooms

- Cold rooms

- Delivery vans

- Transport Chambers

It’s important to note that the monitoring devices used to track temperatures need to be part of any calibration and preventive maintenance program to ensure all environmental monitoring devices remain calibrated for their range of operation.

Our Temperature, Humidity, and Pressure Mapping Capabilities

At Allometrics, we pride ourselves on the quality of our work, and our ability to adapt our services to our client’s specific requirements.

Our temperature, humidity, and pressure mapping capabilities are as follows:

Temperature: -80 – 140 C / 0.5 accuracy

Humidity: 0-90% / accuracy 3-5%

Pressure: 0-5bar / .03 bar accuracy

Duration

Readings can be taken anywhere from once daily to once a second, depending on our customer’s needs. Our mapping service can be run for one or more cycles of your equipment or over a number of days. Many CGMP facilities require temperature mapping to be done for at least one 24-hour time period.

Our mapping services offer many benefits, including:

• Verification of environmental conditions to ensure the stability of the environment and capture any temperature variances.

• Our temperature, humidity, and pressure mapping service are available for a variety of industries, including pharmaceutical manufacturers and distributors, laboratories, crime labs, Departments of Health and Human Services, and other manufacturers.

- Our mapping service is intrinsically safe.

- Customized reporting available.

- We can map a variety of enclosures including autoclaves, controlled environment rooms, freezers, refrigerators, incubators, environmental chambers.

- Our mapping meets FDA requirements and can be customized to meet your quality system.

Call today us to schedule your temperature, humidity, and pressure mapping.