Calibration vs. Certification What’s the Difference?

Many would imagine that calibration vs. certification is of general knowledge, however it is in fact, easily confused. Users of measuring equipment often make the mistake of using the terms certification and calibration interchangeably. Doing so can cause headaches and unnecessary delays and costs.

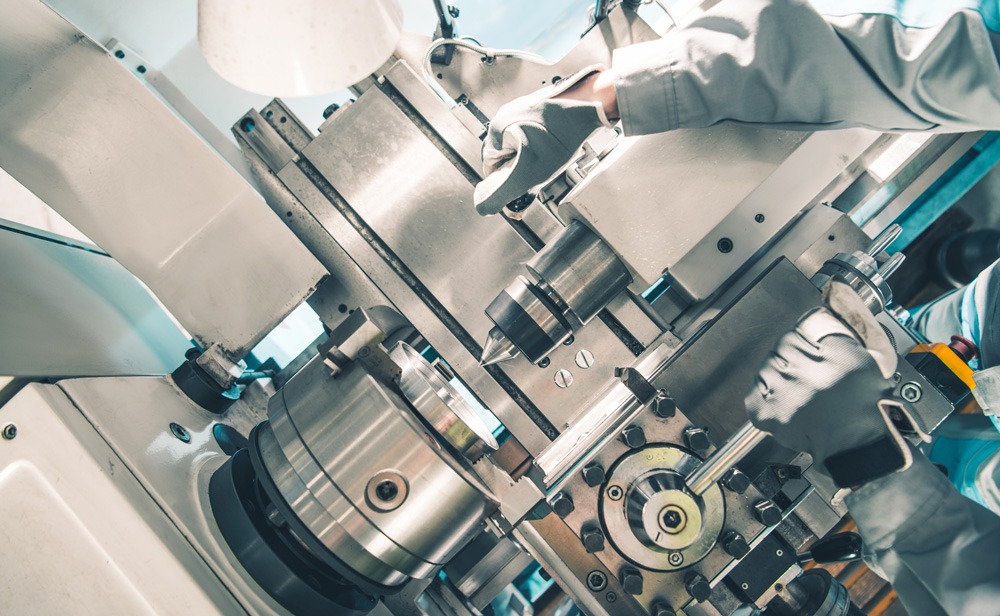

A better understanding of the processes behind these terms can have a significant impact on the reliability of different types of Coordinate Measuring Machines (CMMs).

What is Certification?

The first step to deciphering Calibration vs. Certification is in defining each term. Certification is the process of verifying the performance accuracy of a measuring device at a given point. In other words, when you have your equipment certified, what you are, in fact doing is verifying that it performs within its stated specifications.

Some also use the terms verification and certification interchangeably. However, it’s important to know that verification is the process, and certification is the end result.

Some measuring equipment comes with what is known as a health-check device that allows companies to perform the verification process themselves.

A self-certification is a valuable way for companies to perform regular checks to ensure their equipment continues to work within their specifications.

However, companies should include a third-party certification service. The interval for the certification service will vary depending on the machine and the way its usage, but in general, it involves a yearly or bi-yearly certification.

Third-party certifications provide an extra layer of confidence in the performance accuracy of a machine because these metrology labs employ certified technicians and apply better procedures. Additionally, they have at their disposal better testing equipment with which to perform the verification process.

What is Calibration?

Now that we understand certification, the next step in understanding Calibration vs. Certification is defining calibration. When the verification procedures determine the machine is not performing within its specification; it means it cannot be certified.

The good news is, in most cases when a machine is performing out of spec, a correction is possible. Calibration or recalibration is the process used to bring devices back to working within their specs.

Conducting periodic checks on a CMM, operators can monitor its performance and detect ‘drift’ based on historical data. The moment ‘drift’ is detected, it is a clear sign that a calibration is required.

Additionally, if your equipment is just within tolerance, experts recommend you get it calibrated as the device could go out of tolerance within days or weeks.

Many companies put off having their equipment calibrated for as long as possible thinking this will save them money. Calibration services are more expensive and require more downtime than certifications. However, the truth is that warranty claims, customer complaints, and out of tolerance parts can be far more costly.

Experts recommend you have your instruments calibrated by an ISO 17025 accredited laboratory that provides its customers with before and after data.

These labs will first check the machine and certify its current operational state. If the before data shows the instrument is working within specifications, the customer can feel confident their devices are providing accurate measurements.

However, if the before data shows the equipment shows “drift,” then the customer can choose to have it calibrated by the lab.

If recalibration is requested, then the instrument will be brought back to its original manufacturer specification. One recalibrated, the lab will perform another certification that shows the machine is now operating within specs.

Now that we’ve defined Calibration vs. Certification it is vital to understand that companies shouldn’t attempt to calibrate their equipment. Calibration is a highly technical process that requires expertise and specialized equipment.

For this reason, it is a task best left to the experts that do it day in and day out, and have the proper training, procedures, and equipment to do the job right.

Allometrics is an ISO 17025 Accredited Laboratory with more than 40 years of field and lab calibration experience.

We provide both certification and calibration services for a wide range of instruments across industries. Contact us today for more information.

Allometrics Inc.

At Allometrics, we not only help our customers with understanding the difference between Calibration vs. Certification, we’ve spent the last 40 years helping our customers feel confident that their measurement results are accurate and reliable.

We provide world-class ongoing calibration services to ensure you maximize the performance of your instruments throughout its lifetime.

For more information on our services and capabilities please email us at sales@allometrics.com.