5 Common Calibration Certificate Mistakes

Knowing how to interpret a calibration certificate can help prevent costly mistakes. While most companies realize they require periodic certification of their measuring instruments, not everyone knows how to review them correctly. Today we’ll help you learn h

Information Available on An Accredited Calibration Certificate

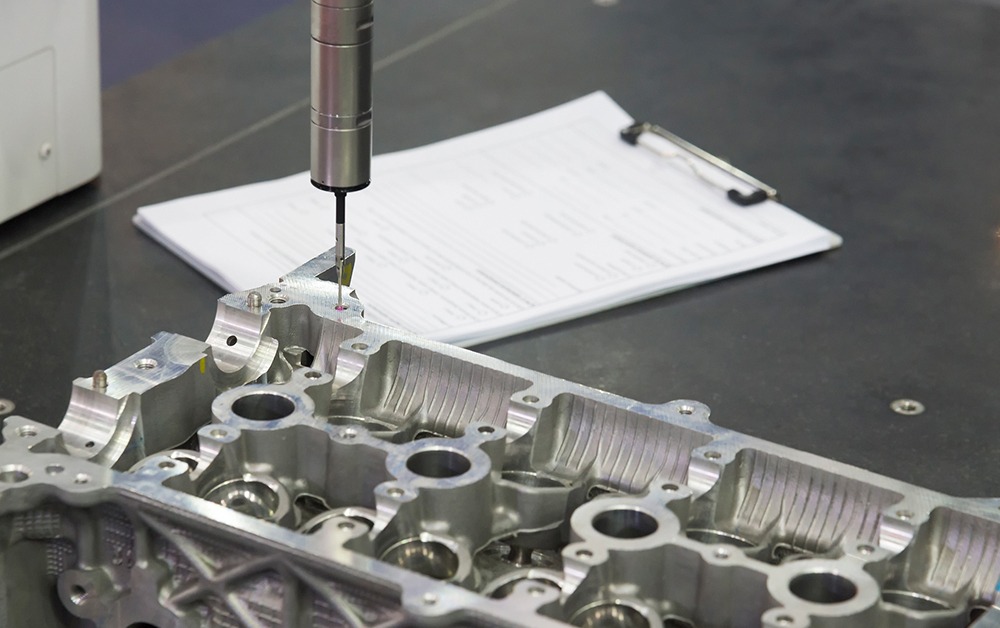

When you need to verify the performance of your instruments or measuring equipment, it’s customary to send it to a third-party laboratory.

If you choose an ISO 17025 accredited metrology lab, you will receive what is commonly known as an accredited calibration certificate, which should include a copy of the lab’s accreditation certificate or ISO 17025 calibration certificate.

An accredited calibration certificate should include all the relevant traceability information, including:

- The specifics of the reference standard used

- The results of the measurement tests

- Any estimated measurement uncertainty results

- The name of the Organization where traceability originates such as the National Institute of Standards and Technology (NIST)

Common Mistakes When Using an Accredited Calibration Certificate

Many companies have their instruments certified because it’s a compliance requirement. However, calibration certificates provide valuable information which needs to be reviewed, understood, and applied when necessary.

Failing to understand the full scope of information provided in a calibration certificate can lead to costly mistakes.

Failing to Review the Information Contained in the Calibration Certificate

While most accredited metrology labs are careful to provide accurate information in their calibration certificates, it is always wise to review the information to ensure there are no errors.

Things to check when you first receive your calibration certificate:

- That the information corresponds to your specific instrument. Check that the certificate list the correct device, it’s model and manufacturer, as well as the serial number. Incorrect serial numbers will effectively invalidate the calibration certificate

- Traceability information. Measurement traceability is crucial because it assures that your measurement results comply with national or international standards.

- Calibration results. Depending on the type of certificate you ordered, the results should include:

- As found and as left results

- Uncertainty results

- Correction/error

Not Applying the Corrector Factor

When you request to have your equipment certified, the results may be that your instruments are within tolerance, or they could turn out to be that the measuring device has some degree of “drift.”

When the test results determine there is “drift,” as the owner, you can choose to have your instruments calibrated by the lab or not.

There will be instances when calibrated instruments cannot be adjusted. In these cases, depending on your industry’s regulations, you can still use the equipment as long as you apply a correction factor whenever a measurement is made.

If you fail to apply the correction factor, you will compromise the safety of your employees and the quality of your product. This can potentially become a costly mistake.

Neglecting to Review Laboratory Remarks

Reviewing the remarks of laboratory technicians is critical when the certified equipment encountered a problem during testing or calibration processes. Here are some examples of observations that need to be paid attention to:

- The device is out of tolerance or failed test

- A limited calibration performed. If you see a similar remark, it means the verification process did not cover the full range of testing required

- Any details of defects found on the equipment or its performance

Not Comparing Results

If your certification includes data about the instrument’s status before and after certification and calibration, it is highly beneficial that you review it.

The benefits of recording the as found/as left data include:

- Determining if the instrument was out of tolerance before the adjustment

- It makes it easy to evaluate the instrument’s performance. The information will let you see if your equipment is providing accurate readings or if they are nearing the accepted limits

- It can help determine the intervals at which your measuring devices require calibration. Knowing this will allow you to schedule calibrations before your equipment falls out of tolerance, saving you time and money

Not Using an ISO 17025 Accredited Laboratory

Not using an ISO 17025 Accredited Metrology lab to certify and calibrate your equipment can be a costly mistake.

Accredited labs are obligated to provide traceability information on their certificates, which will guarantee your instruments are compliant to national, international, and manufacturer standards.

Non accredited labs are not required to provide this information and will leave you wondering if your equipment complies with the standards.

Allometrics is an ISO 17025 accredited full-service calibration and certification company with on-site calibration for most equipment. We are offer NIST traceable conformity testing on all our certification and calibration services.

Contact us today for a quote!

Allometrics Inc.

At Allometrics, we’ve spent the last 40 years helping our customers feel confident that their measurement results are accurate and reliable.

We provide world-class ongoing calibration services to ensure you maximize the performance of your instruments throughout its lifetime.

For more information on our services and capabilities please email us at sales@allometrics.com.