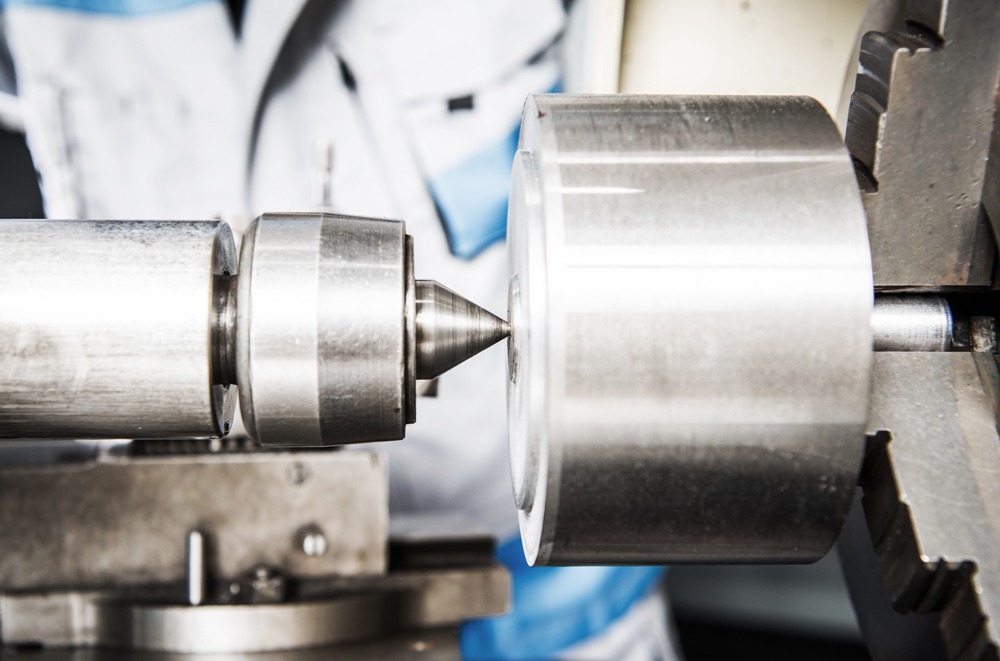

The answer is, yes. Tools really need calibration! Get advise from the experts at Allometrics Inc, a top-rated ISO 17025 accredited calibration company since 1976. Tools are necessary to perform a range of processes in many industries, from manufacturing to environmental science laboratories.

Production and Quality Assurance Management Systems are highly dependent on the correct performance of the tools operators use. So, knowing how well an instrument is performing is imperative.

Verification and calibration are the two processes used to ensure that the measurements provided by the various tools are accurate, precise, and it adheres to national and international standards.

Calibration Standards

Calibration is the process of testing an instrument’s accuracy against known standards.

There are three types of standards used in tool calibration and control systems, namely:

- Primary Standards: High quality and stability units or instruments that are regularly calibrated by the US governing agency National Institute of Standards and Technology (NIST) or by third-party accredited calibration services that have direct traceability to NIST. Primary Standards must be used in a controlled environment.

- Transfer Standards: Instruments or tools with proven stability are calibrated internally by transfer standards from primary standards. Usually, calibration happens in external laboratories under controlled environment conditions. The internal calibration procedures are documented and validated within the quality control system.

- Working Standards: Instruments or equipment with proven stability that are calibrated from transfer standards.

The standards work in sequence. Working standards serve to measure product and process quality, while transfer standards help to calibrate the working standards. Primary standards, on the other hand, are kept at NIST or calibration labs that hold a NIST certification. However, all standards must be traceable to NIST.

Which Instruments Need Calibration

All tools lose some of their accuracies over time as a result of wear and tear and therefore require periodic maintenance that may include calibration.

In broad terms, we can safely say the following equipment must receive periodic calibration to maintain their standard compliance.

- Instruments that use Primary, Transfer or Working Standards

- Any device used in industrial settings to measure product quality

- Any measurement equipment used to measure and monitor the process, including the process inputs or process outputs

We advise our clients to review all their process equipment that has a continuous digital or analog output.

What Should Your Calibration Records Include?

When you have your equipment calibrated by an accredited NIST traceable lab, you will receive a document detailing the procedure used and the results of the verification and calibration processes. You should review and store this document to keep accurate records of your equipment’s maintenance and performance.

Your tool calibration records should cover the following items:

- Tool Number

- Tool Name

- Manufacturer Name (MFG)

- Instrument Location

- Calibration procedure

- Calibration interval

- The transfer standard name used to calibrate the instrument

- The transfer standard tool number

- Date of calibration

- Recommended next due date of calibration

- Calibration record number

- Calibration requirements

- Calibration data

- Technician’s name or signature

- Temperature

- Humidity

- Calibration Results – Accepted/Rejected

The terms used in the calibration certificate can have slight variations, but the information should all be included.

Even the best and most expensive equipment can go off-specification over time; this is why regular calibration is required. Do your tools really need calibration?

Allometrics is an ISO 17025 accredited NIST traceable laboratory with more than forty years of experience servicing industries throughout the Texas gulf coast region and nationwide.

We have a wide range of capabilities servicing many industries. For more information on our services please call us at (281) 336-8930.

Allometrics Inc.

At Allometrics, we’ve spent the last 40 years helping our customers feel confident that their measurement results are accurate and reliable.

We provide world-class ongoing calibration services to ensure you maximize the performance of your instruments throughout its lifetime.

For more information on our services and capabilities please email us at sales@allometrics.com.