Prescription drugs play an essential role in our wellbeing. It is thanks to scientific research in the fields of chemistry, biomedical, pharmaceutical, and medical industries that doctors can cure diseases, slow down the progression of degenerative illnesses, prevent infections, and help save lives.

Therefore, it comes as no surprise that drug manufacturing is one of the most highly regulated industries in the world.

Metrological Regulations for Pharmaceutical Instrument Calibration

To ensure the quality of medications around the world, various regulatory agencies around the globe have established actions to control, maintain, and assure a higher degree of quality of pharmaceuticals.

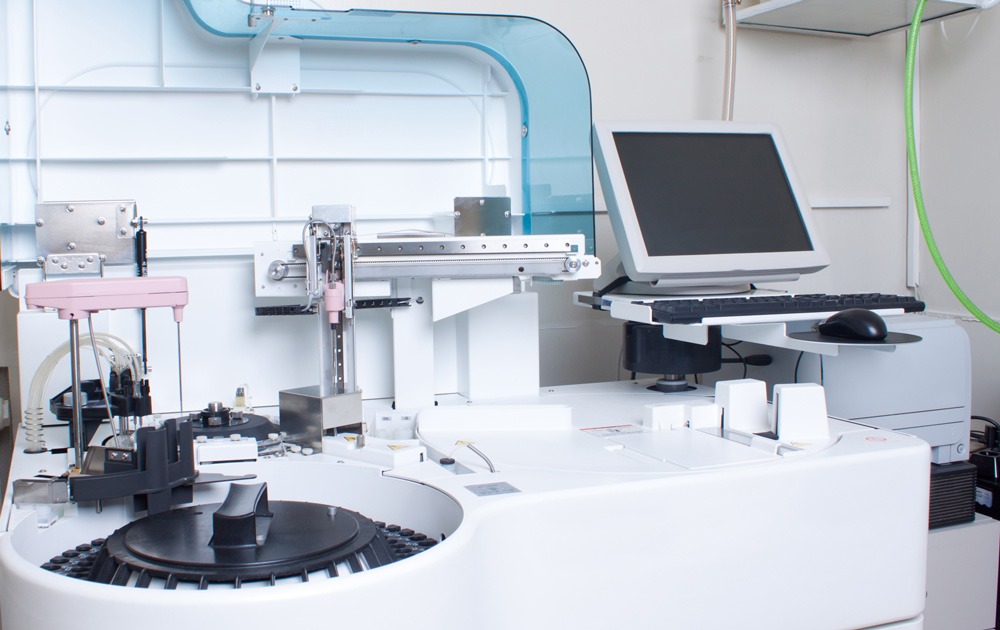

Part of the regulations pertains to testing samples of final products in the Quality Control Laboratory. To ensure the fidelity of the testing results, these facilities require qualified and adequately calibrated or verified equipment and instruments.

The goal is to provide patients with safe and standardized versions of the medications they require. However, if errors in the correct measurement of the physicochemical properties of drug substances occur, pharmaceutical companies risk producing low quality or even harmful products, which can threaten the wellbeing of patients, and cause severe financial damage.

At least one study has linked measurement errors to the use of inadequately calibrated instruments or equipment, evidencing the importance of precise calibration in the pharmaceutical industry.

Given how crucial calibration is for the drug manufacturing industry, the need to establish valid methods, and frequency of equipment calibration became a priority.

However, the industry faced a grave problem; regulatory agencies provided ambiguous guidelines and were slow to adapt to the technological changes, making their regulations obsolete.

The answer to the issue came in the form of independent organizations such as the International Organization for Standardization (ISO) who currently provide guidelines as well as national and international standards to improve industry operations and promote best practices.

Therefore, in addition to the local and global regulations established by the various regulatory agencies, the drug manufacturing industry must also adhere to agreed ISO standards.

Environmental Conditions

Another essential aspect of the pharmaceutical industry is the environmental conditions inside manufacturing and testing laboratories.

Drug companies must comply with the strict federal guidelines that are in place in order to keep the public safe.

USP 797 and USP 800 compliant cleanrooms are a fundamental part of maintaining the ideal conditions for drug manufacturing. USP 797 and USP 800 play a vital role in creating and maintaining contamination free production environments for the pharmaceutical sterile compounding industry.

Additionally, HEPA filtered air circulated in a lamina configuration protects both the lab personnel and the quality of the product.

At Allometrics, we understand how vital patient and employee safety is and how costly measuring mistakes can be. For this reason, we only utilize certified instruments as well as employ NSF accredited and CETA certified technicians to ensure that the equipment and environments used in drug manufacturing and compounding drug labs are safe for everyone.

Allometrics – When Measurements Matter!

Top Rated ISO 17025 Accredited Calibration Company Since 1976.

• NIST traceable calibration

• Climate-controlled Calibration Lab

• Test & Certification

• Equipment Sales