The Value of Air Cleanliness in Compounding Hospital Pharmacies

Good air quality in hospitals is vital for the safety of patients, their families, and hospital staff. According to the Centers for Disease Control and Prevention (CDC), 1 in 25 patients acquires an infection while hospitalized.

Identifying the source and method of transmission has always been a challenge. Over the years, proposed solutions seem to center more on hand hygiene rather than preventing the aerial dissemination of bacteria.

One hospital area which has embraced a more pluralistic approach to preventing healthcare-associated infection (HAI) has been hospital compounding pharmacies.

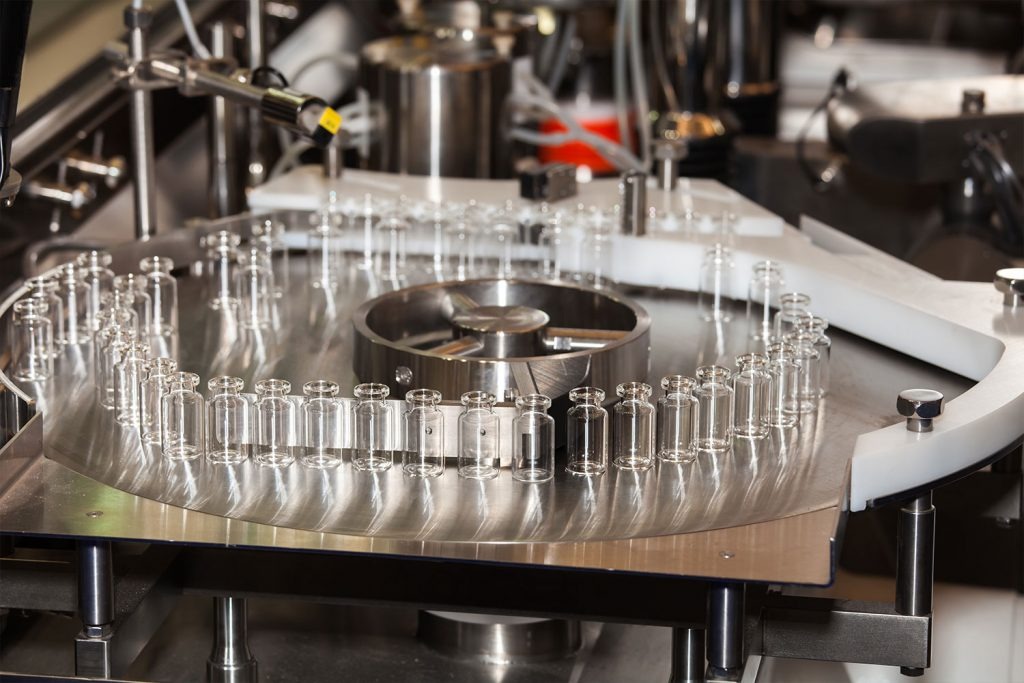

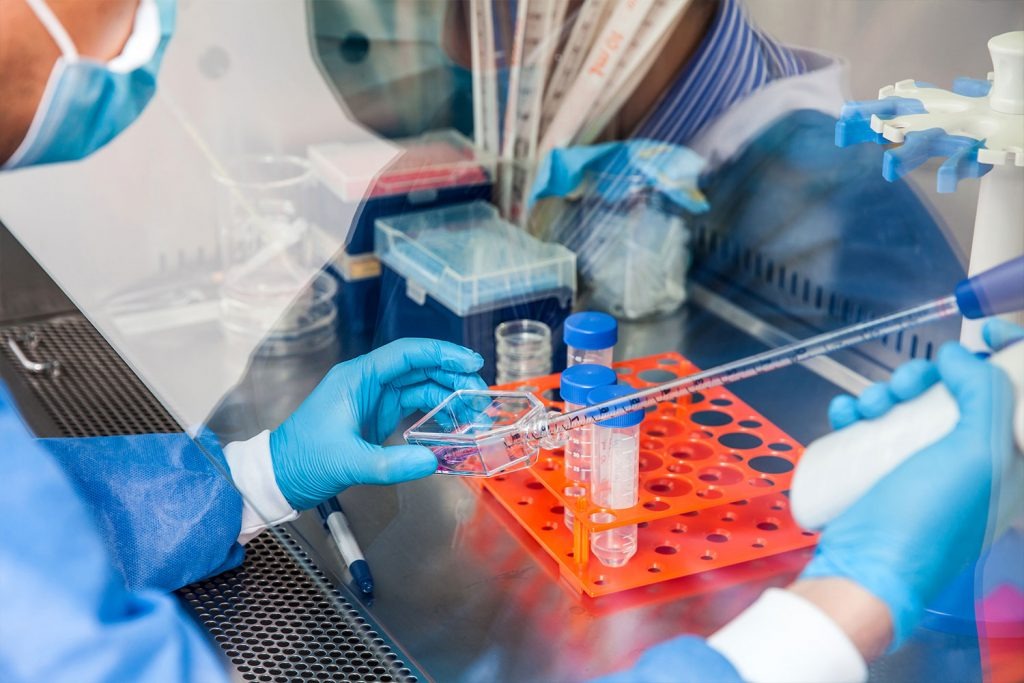

The pharmacies must utilize certified cleanrooms and gloveboxes, as well as biological safety cabinets, while manufacturing drugs for patients whether they are hospitalized or treated as outpatients.

USP 797 and USP 800 Certified Cleanrooms

The United States Pharmacopoeia issued its environmental regulatory guidelines for compounded sterile preparations (CSPs) in a document known as USP 797.

Aside from providing the standards for purity, quality, strength, and consistency, the USP 797 standard also regulates other factors having to do with the cleanroom requirements as well as:

- HVAC Systems

- Humidity, Temperatures, and Pressure

- Equipment Maintenance

- Testing Procedures

While USP 797 governs the manufacture of compounded sterile preparations, USP 800 was designed to safeguard patients and healthcare personnel who come in contact with hazardous drugs. In both cases, regular cleanroom certification is necessary.

Primary Engineering Controls (PECs)

A PEC is a room or device such as laminar airflow workbenches (LAFWs), biological safety cabinets (BSCs), compounding aseptic isolators (CAIs), and compounding aseptic containment isolators (CACIs) that provides an ISO Class 5 environment for compounding CSPs.

All PECs rely on a specific type of high-efficiency particle air (HEPA) filter that is >99.99% efficient in removing particles as small as 0.3 microns in size.

PEC airflow must be unidirectional either vertical or horizontal, and to maintain this unidirectional flow during the preparation of CSPs while at the same time sweeping particles away from the compounding area, the HEPA filtered air must provide a sufficient and constant velocity. Therefore, regular testing of the PEC airflow is necessary to verify it’s unidirectional, and there are no turbulence or reverse flows.

How Frequent Do Cleanroom Inspections Need to Be?

USP guidelines state that air sampling shall be performed at least every six months as part of the requirements for re-certification of the compounding facility and its equipment.

However, these are just the minimum standards, each compounding facility is different, and some may require more frequent testing.

A good practice which many compounding facilities do is to continuously monitor for viable particles such as viruses and bacteria.

Continuous particle counting, coupled with correctly set alarms, can help identify issues such as a gap in a door seal or a malfunctioning piece of air handling equipment before the wellbeing of patients and laboratory staff is compromised.

Nonviable Airborne Particle Testing

The ISO classification of a cleanroom or PEC device depends on nonviable particle testing or certification. The certification must be done by qualified personnel and in direct compliance with the Certification Guide for Sterile Compounding Facilities.

At Allometrics, our NSF Accredited Technicians, and CETA certified cleanroom professionals for sterile compounding facilities work hard to keep cleanrooms, gloveboxes, and biological safety cabinets used in the manufacture of drugs used in hospitals USP compliant.