Why is Metrology So Important?

In the manufacturing industry and in emerging technologies, measuring has become an indispensable tool. Consequently, the science of metrology was developed in response to the need to standardize measurements.

What is Metrology?

Metrology is the study of measurement and a key component in achieving accuracy. Metrology aims to provide accurate and reliable measurements in various applications, including manufacturing, health, and environmental sciences. Additionally, metrology is uniquely important as it provides the basis for quality assurance programs in manufacturing processes and research and development.

When applied correctly, it’s easy for metrology to go unnoticed and therefore runs the risk of being undervalued and under-appreciated.

Types of Metrology

The International Bureau of Weight and Measures states that metrology embraces experimental and theoretical determinations in any field of science and technology.” As such, there are three main types of metrology.

Scientific Metrology

This field concerns the establishment of new units, standards, and measurement methods. As its name suggests, scientific metrology involves much research and forms the basis for all the other branches.

Applied Metrology

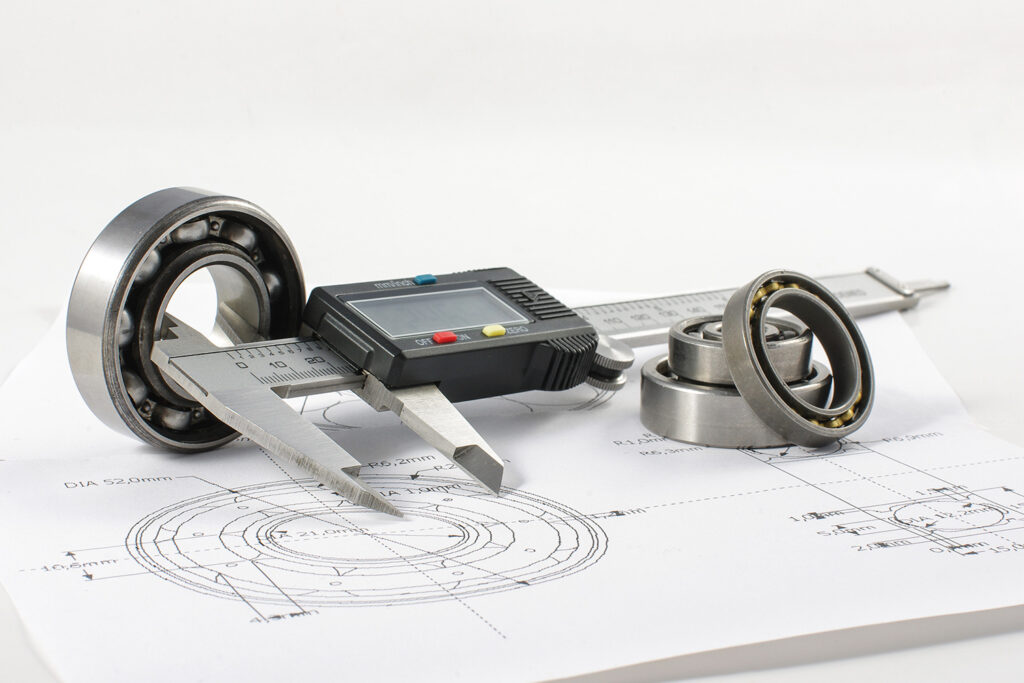

Also known as industrial metrology, this deals with the application of measurement in industrial or manufacturing processes.

Applied metrology seeks to assess and standardize the accuracy and precision of measuring equipment. Calibration is a vital aspect of applied metrology as it ensures the functionality and precision of measuring instruments, which are critical to quality control.

Legal Metrology

The legal branch concerns itself with the regulatory requirements of measurements in different industry sectors, including measurement units and methods.

Legal metrology aims to ensure fair trade, ensure public safety, protect consumer rights, protect the environment and enable taxation.

The Role of Metrology in Manufacturing and General Mechanics

The world of manufacturing has come a long way since the start of the industrial revolution. Nowadays, production lines produce millions of different parts and components daily with little human intervention.

Each machine in the production line produces specific parts based on precise specifications and measurements within a maximum permissible error (MPE) or tolerance for error.

However, with time, use, and environmental factors, even the most sophisticated and expensive machines can lose alignment and fall out of tolerance. These shifts, even when small, can compromise the entire production line. Deviations in measurements can result in costly product recalls and compromise the safety of consumers.

In the manufacturing industry, metrology plays a critical role in identifying and correcting inaccuracies in measuring. Regular calibration enables manufacturers to produce more accurate, safer products and adhere to higher standards of quality. Well-calibrated equipment can also help reduce manufacturing costs and downtime.

Why Choose Allometrics as Your Calibration Partner?

An effective calibration requires attention to detail, knowledge, skills, and a comprehensive testing capability.

At Allometrics, we are experts in calibration. For the last 47 years, we’ve been helping companies comply with regulations, minimize the risk of costly measurement inaccuracies, extend the life of their equipment, and in the long-run save money.

Allometric is accredited by the American Association for Laboratory Accreditation (A2LA) and registered with ISO/IEC 17025. We also regularly invest in our technicians’ continued education, ensuring that they are knowledgeable about the industry’s best practices and protocols.

All our calibrations are NIST traceable, and we endeavor to tailor our calibration certifications to your company’s needs.

Additional benefits of working with Allometrics:

- Fast Turnarounds

- On-site calibration services are available

- Knowledgeable and experienced calibration technicians

- Top-rated customer service

Call us today for assistance with your calibration needs!