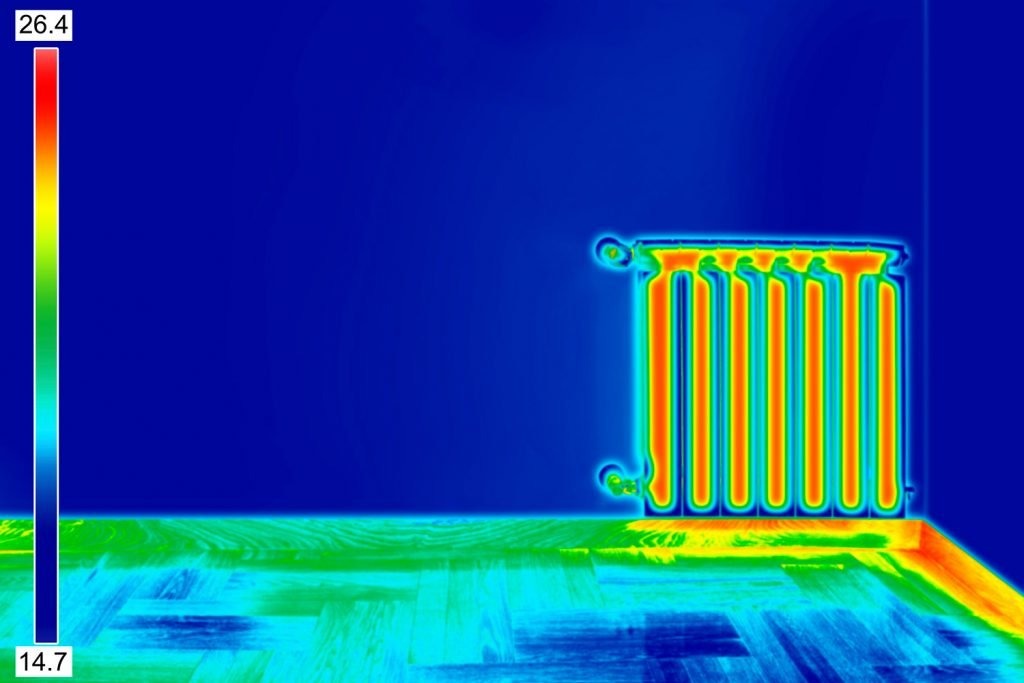

Temperature mapping, or thermal mapping as it’s sometimes called, is an excellent manufacturing and storage practice for food, electronics, and pharmaceutical companies to help monitor and maintain ideal environmental conditions.

Even minor fluctuations in temperature can mean falling out of compliance with industry regulatory requirements and potential costly inventory losses.

As such, periodic temperature mapping of manufacturing and storage conditions is critical to prevent temperature and humidity fluctuations within a climate-controlled area, be it a refrigerator, a warehouse, or vehicle.

How It’s Done

Temperature mapping is necessary for any environment within your factory where the quality of a product can be affected by temperature or humidity variations.

Technicians place data loggers in strategic places throughout the testing site to map the temperature and humidity of the area. The loggers collect data for at least 24 hours to study temperature and humidity distribution throughout the day.

The data gathered allows technicians to identify inconsistencies and provide accurate assessments and solutions to company owners. The causes of the discrepancies found are often due to opening and closing of doors, faulty seals, the heat produced by equipment, or a failing HVAC system.

Before the mapping process begins, some important points need consideration, such as:

- The location of windows, doors, loading bays, and HVAC ventilation outlets since these can cause temperature fluctuations

- Where the highest volume of storage is

- Whether the space includes a mezzanine or other storage areas

With this and other pertinent information on hand, the technicians can determine the number of data loggers required. Their placement must be in a grid formation to ensure the readings provide accurate and thorough information.

Reporting and Assessing the Data

Once the temperature mapping testing is complete, the data collected will show any deficiencies or inconsistencies found.

This information is critical to determine if any permanent temperature monitoring equipment such as thermometers needs repositioning or calibration. In addition, the areas with the most significant temperature and humidity variations indicate where the products are most vulnerable.

Your temperature mapping can also identify areas unsuitable for storing medications, vaccines, and other susceptible products. If this is the case, storage racks will need relocating to more temperature stable areas.

The data provided through a temperature mapping exercise is integral to the validation process necessary to comply with the different regulatory guidelines and ensure your company maintains Good Manufacturing Practices.

Beyond Temperature Mapping

Once you’ve completed and addressed any issues identified during the temperature mapping, the next step is to monitor and maintain your factory’s ideal temperature and humidity settings.

That’s where temperature monitoring comes into play. A suitable temperature monitoring protocol will involve using temperature measurement equipment such as thermometers and data loggers to record variations that can be analyzed regularly.

Thermometers require periodic calibration and recalibration to ensure you maintain accurate temperature settings in your storage or manufacturing areas.

At Allometrics, we provide high-level temperature mapping, thermometer calibration, and recalibration services for an array of applications.

Our certified technicians have ample field experience and follow current Good Manufacturing Practices and safety protocols.

Call us today to learn more about our services and how we can help you minimize product recalls and inventory loss while remaining compliant with U.S. Food and Drug Administration (FDA) and other pertinent regulatory agencies.

Allometrics Inc.

Allometrics is the ideal calibration service provider, with more than 40 years of calibration experience, a wide range of capabilities and a state-of-the-art controlled environment lab at our disposal, we can help you achieve your calibration goals.

For more information on our services and capabilities please email us at sales@allometrics.com.